KACAB Teknik AB has an ever-growing range of quality products at good prices!

If you have a special demand or requirement for a product, with KACAB´s decades of experience, our expertise can always provide you with fast help and the very best solutions

Do not hesitate to contact us - We are experts in Shrink Tubing and Cable Ties

Click on the link below if more info is desired

Heat Shrink Tubing Guide Learn about heat shrink tubing

Select the correct tubing

The choice of heat shrink tube is thus influenced by the conditions of the application. The ambient temperature, the desired degree of shrinkage and whether the shrink tubing should be adhesive-coated or not are some issues that affect the choice of heat shrink tubing.

We have also compiled some simple questions that facilitate the selection of heat shrink tubing up to 1000V.

Questions to help you

Is it for general use or are there special requirements?

Special requirements can be, for example, high temperature, chemical resistance, other approval / certificate or labeling.

With or without adhesive?

An adhesive-coated shrink tubing has a layer of hot melt adhesive on the inside that essentially fulfills two functions. To create a moisture barrier and also a better grip between cable and shrink tube. Adhesive lined shrink tubing is sometimes called dual wall.

What diameter and degree of shrinkage (shrinkage capacity) is needed?

In addition, size should be chosen so that shrinkage occurs by at least 20% and a maximum of 80%. The degree of shrinkage therefore tells how much the shrink tubing shrinks. Example of a degree of shrinkage 3: 1 with an unchrimped diameter of 45 mm shrinks down to 15 mm. Some shrinkage may also occur on the length of the tubing.

What wall thickness is needed?

There is a thin / medium / heavy-walled heat shrink tubing. The wall thickness of the shrink tubing is always defined at maximum shrinkage. This means that the heat shrink tubing is always thinner before installation. A thin walled shrink tubing is more flexible, can be delivered on a roll and it shrinks faster. A thick-walled shrink tube insulates better and also provides better mechanical protection against abrasion.

Heat shrink tubing

The shrink tubing range includes:

• Thin walled shrink tubing • Medium walled shrink tubing • Heavy walled shrink tubing • Single wall, dual wall • Heat shrink tubing in different lengths & on roll • Flame retardant shrink tubing • Shrink tubing with glue and shrink tubing without glue • Shrink tubing made of polyolefin (POX) , Fluoropolymer (FPM), polyvinylidene fluoride (PVDF) and polytetrafluoroethylene (PTFE) etc.

The shrink tubing is available in different shrinkage ratios from 2: 1 up to 6: 1 for different applications.

How to shrink heat shrink tubing?

You can find the best tips here:

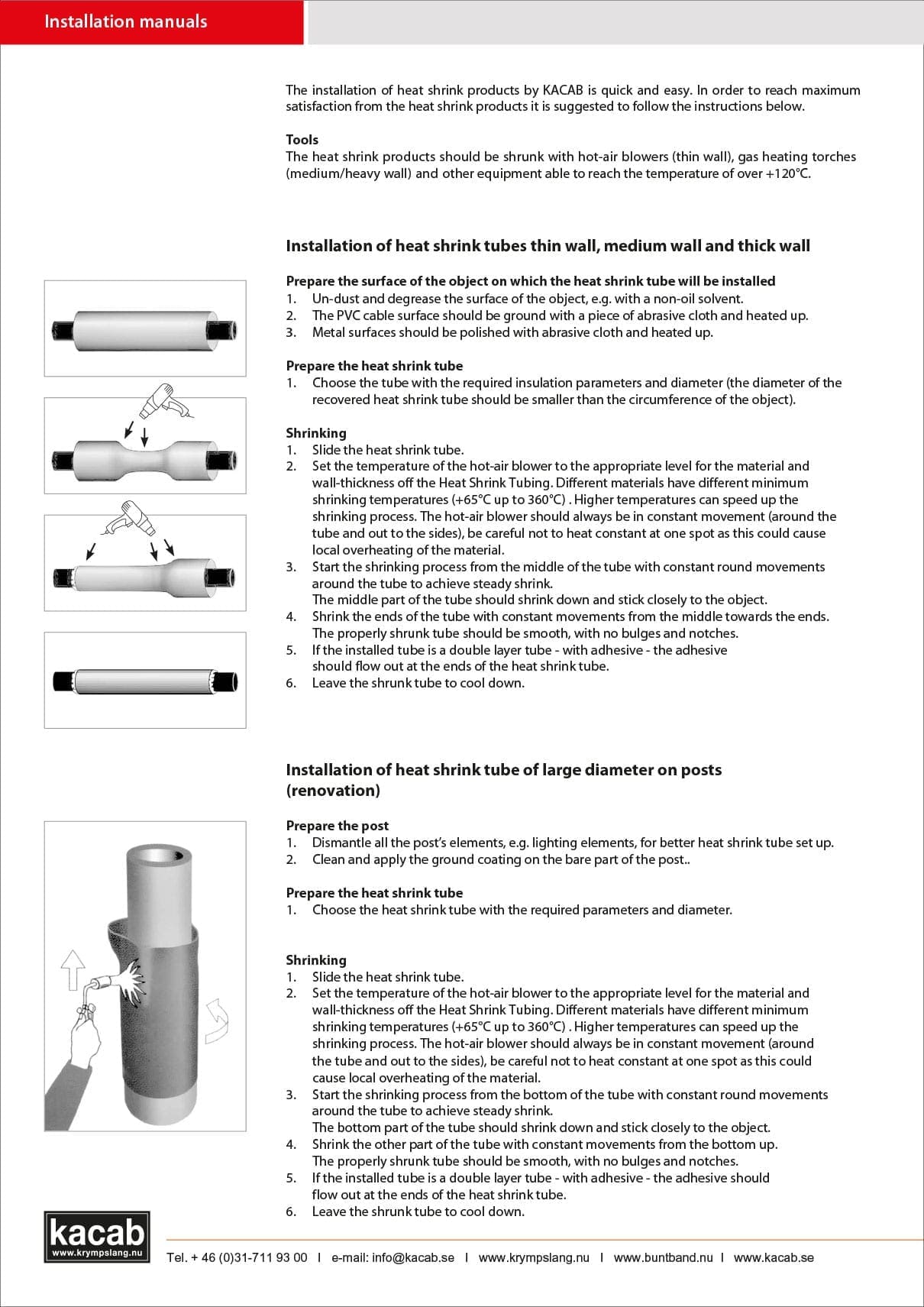

1. When heat shrink tubing is to be heated, it is recommended to first start in the middle of the tubing, then gradually move towards one end and then from the middle again towards the other end. Because in this way you can avoid air pockets in the heat shrink.

2. Heat shrink may also sometimes on the length. You should therefore take this into account when cutting the shrink tube.

3. If the object to be covered is made of metal or heat-conducting,it must be carefully ensured that the object is preheated to avoid “cold spots” or “cold marks”. It guarantees a snug and even fit of the tube.

4. When cutting the shrink tubing and cuffs to desired length, make sure the ends are smooth. Carelessly cut and uneven edges can cause the heat shrink tubing and cuffs to crack during shrinkage.

5. When choosing the size of the shrink tubing, it is important to consider the 80:20 rule. This means that the hose size must be chosen so that the shrinkage is at least 20% and at most 80%.

6. Finally, when shrinking, always ensure that the workplace is well ventilated and that you wear personal protective equipment such as gloves and safety glasses.

What are the most important parameters for the right choice of heat shrink tubing?

Wall thickness:

Namely, the thickness of the material must be stated in millimeters after complete shrinkage. “Nominal” defines the dimensions without any tolerances.

In general, you can choose between thin walled, medium walled and heavy walled shrink tubing. thin walled, medium walledand heavy walled shrink tubing . Heat shrink tubing is also available with adhesive. It is sometimes called dual wall shrink tubing.

Heat shrink tubing diameter:

For thin-walled hoses with a shrinkage ratio of 2:1 (standard), the diameter is usually given in inch sizes, where 25.4 mm corresponds to 1 inch.

Shrink ratio:

Depending on the material and also the wall thickness, the shrink tube can first be expanded to varying degrees.

A shrinkage ratio shows the velocity and the shrinkage rate of the product (diameter in relation to the recovered diameter). The shrinkage ratio varies from 2:1 to 6:1. The higher the shrinkage ratio, the more variable the shrinkage diameter, thus fewer sizes of heat shrink tubing are needed, which helps to reduce bearings and requires less bearing space.

Longitudinal shrinkage:

Heat shrink tubing may sometimes also shrink to a shorter length. This change in length after shrinkage is stated in percent.

Minimum shrinkage temperature:

Not all heat shrink tubing shrinks at the same temperature. It largely depends on the type of material and also the wall thickness.

Operating temperature:

The operating temperature also varies with shrink tube type. It thus depends on which material was used for resp. tubing type. When choosing the right size, it is recommended to follow the 80:20 rule as described earlier above, under Heat shrink tubing sizes.

Overall, heat shrink tubing is thus widely used in wiring harness assembly. Heat shrink tubing can also be used for insulation, cable identification, mechanical protection and finally also aesthetic design.

So how do you shrink shrink tubing?

The best tips can be found here:

1 . When the shrink tubing is to be heated, it is recommended to start in the middle of the tubing, then gradually go towards one end and then from the middle again towards the other end. This way you can avoid air pockets in the hose.

2. Heat shrink may also sometimes on the length. You should take this into account when cutting the heat shrink tubing.

3. If the object to be covered is made of metal or heat-conducting,it must be carefully ensured that the object is preheated to avoid “cold spots” or “cold marks”. It guarantees a snug and even fit of the tube.

4. When cutting the shrink tubing and cuffs to desired length, make sure the ends are smooth. Carelessly cut and uneven edges can cause the heat shrink tubing and cuffs to crack during shrinkage.

5. When choosing the size of the shrink tubing, it is important to consider the 80:20 rule. This means that the hose size must be chosen so that the shrinkage is at least 20% and at most 80%. Detailed examples of how to choose the right shrink tubing can be found in our catalog, in the section insulation products.

6. Finally, when shrinking, always ensure that the workplace is well ventilated and that you wear personal protective equipment such as gloves and safety glasses.

What are the most important parameters for the right choice of heat shrink tubing?

Wall thickness:

Namely, the thickness of the material must be stated in millimeters after complete shrinkage. “Nominal” defines the dimensions without any tolerances.

In general, you can choose between thin walled, medium walled and heavy walled shrink tubing. thin walled, medium walledand heavy walled shrink tubing . Heat shrink tubing is also available with adhesive. It is sometimes called dual wall shrink tubing.

Heat shrink tubing diameter:

For thin-walled hoses with a shrinkage ratio of 2:1 (standard), the diameter is usually given in inch sizes, where 25.4 mm corresponds to 1 inch.

Shrink ratio:

Depending on the material and also the wall thickness, the shrink tube can first be expanded to varying degrees.

A shrinkage ratio shows the velocity and the shrinkage rate of the product (diameter in relation to the recovered diameter). The shrinkage ratio varies from 2:1 to 6:1. The higher the shrinkage ratio, the more variable the shrinkage diameter, thus fewer sizes of heat shrink tubing are needed, which helps to reduce bearings and requires less bearing space.

Longitudinal shrinkage:

Heat shrink tubing may sometimes also shrink to a shorter length. This change in length after shrinkage is stated in percent.

Minimum shrinkage temperature:

Not all heat shrink tubing shrinks at the same temperature. It largely depends on the type of material and also the wall thickness.

Operating temperature:

The operating temperature also varies with shrink tube type. It thus depends on which material was used for resp. tubing type. When choosing the right size, it is recommended to follow the 80:20 rule as described earlier above, under Heat shrink tubing sizes.

Overall, heat shrink tubing is thus widely used in wiring harness assembly. Heat shrink tubing can also be used for insulation, cable identification, mechanical protection and finally also aesthetic design.