Guide to our Shrink Tubing!

Choose the right shrink tubing:

The choice of heat shrink tubing is affected by the conditions of the application. The ambient temperature, the desired degree of shrinkage and whether the shrink tubing should be adhesive-coated or not are some issues that affect the choice of heat shrink tubing.

We have compiled some simple questions that facilitate the choice of shrink tubing up to 1000V.

Questions to help you:

Is it for general use or are there special requirements?

Special requirements can be, for example, high temperature, chemical resistance, other approval / certificate or labeling.

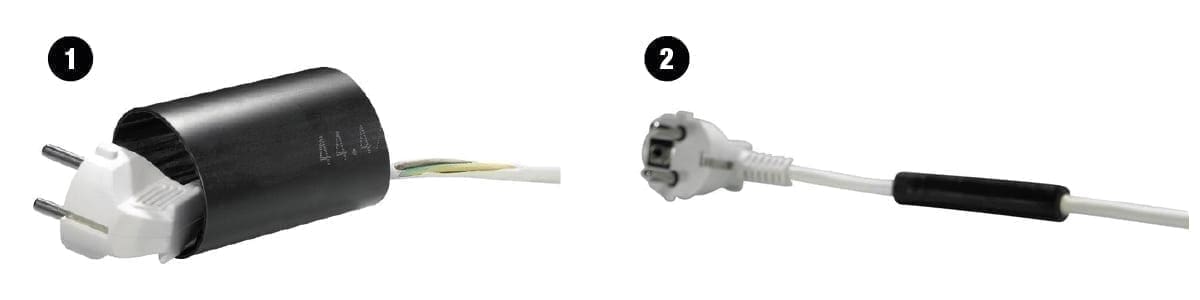

With or without adhesive?

An adhesive-coated shrink tubing has a layer of hot melt adhesive on the inside that essentially fulfills two functions. To create a moisture barrier and a better grip between cable and shrink tubing. Adhesive lined shrink tubing is sometimes called dual wall.

What diameter and degree of shrinkage (shrinkage capacity) is needed?

Size should be chosen so that shrinkage occurs by at least 20% and a maximum of 80%. The degree of shrinkage tells you how much the shrink tubing shrinks. Example of a degree of shrinkage 3: 1 with an unchrimped diameter of 45 mm shrinks down to 15 mm. Some shrinkage may also occur on the length of the tubing.

What wall thickness is needed?

There is a thin / medium / heavy-walled heat shrink tubing. The wall thickness of the shrink tubing is always defined at maximum shrinkage. This means that the heat shrink tubing is always thinner before installation. A thin walled shrink tubing is more flexible, can be delivered on a roll and it shrinks faster. A heavy walled shrink tubing insulates better and provides better mechanical protection against abrasion.

Heat shrink tubing

The shrink tubing range includes:

• Thin walled shrink tubing • Medium walled shrink tubing • Heavy walled shrink tubing • Single wall, dual wall • Heat shrink tubing in different lengths & on roll • Flame retardant shrink tubing • Shrink tubing with glue and shrink tubing without glue • Shrink tubing made of polyolefin (POX) , Fluoropolymer (FPM), polyvinylidene fluoride (PVDF) and polytetrafluoroethylene (PTFE) etc.

The shrink tubing is available in different shrinkage ratios from 2: 1 up to 6: 1 for different applications.

Click here to read more about how to choose the right shrink tubing